AUCTORES

Globalize your Research

Research Article | DOI: https://doi.org/10.31579/2693-4779/158

Dokuz Eylül University, Engineering Faculty, Department of Environmental Engineering, Tınaztepe Campus, 35160 Buca/Izmir, Turkey.

*Corresponding Author: Delia Teresa Sponza, Dokuz Eylül University, Engineering Faculty, Department of Environmental Engineering, Tınaztepe Campus, 35160 Buca/Izmir, Turkey.

Citation: Delia T. Sponza, Rukiye Öztekin, (2023), Photocatalytic H2 Production from Hydrazine Monohydrate (N2H4.H2O) using Ni–W–O Nanocomposite, Clinical Research and Clinical Trials, 8(2); DOI:10.31579/2693-4779/158

Copyright: © 2023, Delia Teresa Sponza. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received: 16 August 2023 | Accepted: 15 October 2023 | Published: 04 December 2023

Keywords: hydrazine monohydrate (n2h4.h2o); hydrogen [h2(g)] production; ni–w–o nanocomposite; photocatalytic degradation

In this study, H2(g) was produced from hydrazine monohydrate using Ni–W–O nanocomposite. The XRD pattern of the synthesized hydrothermal of Ni–W–O nanocomposite samples exhibited some features of that of NiWO4 with poorly crystallized groups. FTIR spectra of the nanocomposite showed an intense peak at 822 cm−1 corresponding to the stretching vibrations of O–W–O. TEM analysis indicated the reduction of the small NiWO4 crystallites during production process. In the EDS analysis Ni and W elemental distributions was detected. XPS results shows the presence of Ni (II) and W(VI) at high-temperature annealing. For maximum photodegradation of hydrazine monohydrate (N2H4.H2O) to H2(g) (2.670 l) the conditions were as follows: Ni–W–O nanocomposite concentration of 2 mg/l with a Ni/W/O ratio of 0.8/0.5/0.2, 80 min irradiation time, a ligth power of 90 W/m2, a temperature of 60oC and a pH of 8.0.

Hydrogen (H2) is expected to play an essential role as an energy carrier in the future clean energy economy based on renewable energy resources. However, the widespread utilization of hydrogen is hampered by the technical difficulty involved in hydrogen storage and delivery [1]. The materials capable of reversible dehydrogenation have long been sought as possible candidates for high-capacity hydrogen storage [2]. However, none of the existing materials met the requirements for hydrogen capacity (over 6 wt%), kinetics, and operation temperature. Recently, chemical hydrogen storage involving hydrolysis or thermolysis of hydrogen-rich materials and spent-fuel regeneration has emerged as a competitive alternative to a high-pressure hydrogen cylinder for vehicular and portable applications [3]. Among the hydrogen-rich materials of interest, hydrazine monohydrate (N2H4.H2O) is an appealing candidate thanks to its favorable combination of low cost, high hydrogen capacity (8.0 wt%), and good stability at ambient temperatures [4]. In particular, the decomposition reactions of N2H4 yield only gaseous products, which is highly beneficial for the design and practical application of H2-source systems. A series of multicyclic bis(hydrazine) and bis(diazenium) compounds connected by relatively rigid hydrocarbon frameworks were prepared for the study of intramolecular electron transfer. The thermodynamics of electron removal of these compounds was investigated by cyclic voltammetry. The difference between the first and second oxidation potentials for the 4 sigma-bonded species was found to be larger for the bis(hydrazyl) radical systems than for the bis(hydrazines) by ca. 0.2 V (4.6 kcal/mol). This indicates a greater degree of interaction between the two nitrogen moieties for the hydrazyl systems, which is consistent with a greater degree of electronic coupling (H {rm AB}) in these systems [5]. The development of N2H4.H2O as a chemical hydrogen storage material requires highly active and selective catalysts for promoting hydrogen production, and meanwhile suppressing the formation of NH3. In the past decades, a number of transition metals/alloys have been investigated in terms of catalytic properties toward N2H4.H2O decomposition [6]. It was found that alloying is a highly effective approach for boosting the catalytic performance toward HP from N2H4.H2O. The alloying aspect could be understood from two complementary effects: the geometric and electronic modifications of the catalyst surface [6-15]. The bimetallic alloys composed of a combination of precious metals (like Pt and Ir) and nonprecious metals (like Ni, Co, and Fe) generally exhibited favorable performance in both activity and H2(g) selectivity [16-20]. In contrast, the catalytic activity of the noble-metal-free alloys is typically inferior. For instance, the reaction rates of N2H4.H2O decomposition over the representative Ni-based catalysts, such as NiCu/CeO2, NiFe/W. CeO2, NiCo/NiO−CoOx, and NiMo/NiMoO, were 1 or 2 orders of magnitude lower than those of the NiPt and CoPt catalysts [21-27]. Currently, the less favorable modification effects of non-precious metals compared to noble metals are still poorly understood, but from the perspectives of the cost reduction and growth potential, non-precious-metal catalysts represent an important direction for future research of the N2H4.H2O-based HP technology. In general, activity improvement of non-precious-metal catalysts can be pursued via composition/phase tuning and structure optimization.

Therefore, in this study, H2(g) production from N2H4.H2O photodecomposition was studied using Ni−W−O-derived nanocatalyst. Operational conditions such as temperature (20, 30, 40, 50, 60, 70, 80 , 90, 100 and 110oC), nanocomposite concentration (0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5 and 4 mg/l ), illuminating time (20, 30, 40, 50, 60, 70 , 80 and 120 min), ligth power (20, 30, 40, 50, 60, 70, 80, 90, 100 and 110 W/m2), pH (4.0, 7.0, 8.0, 9.0, 10.0, 11.0 and 12.0) and Ni/W/O ratios (0.2 / 0.5 / 0.8, 0.5 / 0.8 / 0.2 and 0.8 / 0.5 / 0.2 ) in the Ni-W-O nanocomposite influencing the H2(g) production was examined. The physicochemical properties of the Ni−W−O- nanocatalyst produced under laboratory conditions was investigated with X-ray diffraction (XRD), transmission electron microscopy (TEM), Fourier transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS).

Firstly, 2.2 mmol of Na2WO4.2H2O was dissolved into 25 ml of DI water, then 1 g of NiCl2.6H2O was added to the aqueous solution. The mixture was stirred for 30 min. The obtained mixture was transferred to an autoclave and kept at 180°C for 4 h. The sample was collected after cooling to ambient temperature and was sequentially washed with deionized water and C2H5OH and then dried under vakuum at 80°C for 1 h. The samples was annealed at different temperatures (350, 400, and 600 °C) for H2(g) production during 100 min.

The structure of the Ni-W-O nanocomposite were characterized by X-ray diffraction (XRD, 2000 using Cu Kα monochromatized radiation), transmission electron microscopy (TEM, JEOL-2100F), Fourier transform infrared spectroscopy (FTIR, Nicolet IS10), Raman spectroscopy (Thermo Scientific DXR with an excitation wavelength of 532 nm), and X-ray photoelectron spectroscopy (XPS, Thermo Scientific using an Al Kα X-ray source). In the XPS studies, carbon was used for calibration of the binding energy scale.

Hydrazine was measured by ultraviolet–visible spectroscopy at a wave lentgh of 560 nm (UV–vis, 220).

N2H4.H2O solution containing the Ni-W-O nanocomposite catalyst and an alkaline aqueous solution was preheated at the desired temperature under magnetic stirring. The generated gaseous products passed through a 1.0 M hydrochloric acid solution to absorb ammonia, if any, and then were measured by the water-displacement method using an electronic balance with a precision of ±0.01 g. In the test of the catalytic decomposition properties of concentrated N2H4.H2O solution, an online mass flowmeter equipped with a silica drier was used to monitor the volume of the gaseous products. The reaction rate was evaluated at a reactant conversion of 50%, assuming all the Ni atoms take part in the catalytic reaction. The H2(g) was measured with a Dragger H2 gas meter.

The concentrations of Ni-W-O nanocatalyst was increased from 0.5 mg/l up to 4 mg/l. The maximum H2(g) production was ontained with 2 mg/l Ni-W-O concentration as 2.670 l (Table 1). The increase of nanocatalyst concentration to 3 and 4 mg/l did not affect the H2(g) production.

| Ni-W-O nanocatalyst concentration (mg/l) | H2(g) production ( l ) |

| 0.5 | 0.800 |

| 1 | 1.000 |

| 1.5 | 1.870 |

| 2.0 | 2.670 |

| 2.5 | 2.300 |

| 3.0 | 2.200 |

| 3.5 | 2.000 |

| 4.0 | 2.000 |

Table 1. Effect of increasing Ni-W-O nanocatalyst concentration on H2(g) production efficiency

Catalytic properties toward N2H4.H2O photodegradation were studied on the Ni–W–O derived nanocomposite catalysts. According to control experiments, changing the molar ratio of Ni/W precursors caused a variation of catalytic properties toward N2H4.H2O decomposition, and the optimal Ni/W precursors molar ratio was determined. Therefore, the Ni/W/O ratios was adjusted to 0.2 / 0.5 / 0.8, to 0.5 / 0.8 / 0.2 and to 0.8 / 0.5 / 0.2 in the 2 mg/l Ni-W-O nanocomposite (Table 2). Among these ratios the maximum H2(g) production was detected with a Ni/W/O ratio of 0.8/ 0.5/ 0.2.

| Ni / W / O ratios | H2(g) production ( l ) |

| 0.2 / 0.5 / 0.8 | 1.450 |

| 0.5 / 0.8 / 0.2 | 1.600 |

| 0.8 / 0.5 / 0.2 | 2.765 |

Table 2. Effect of Ni-W-O ratios in the Ni-W-O nanocatalyst on H2(g) production efficiency

As shown in Table 3, the cumulative H2(g) production was linearly correlated with illumination time. As the time increased from 20 min up to 80 min the H2(g) production increased from 2 l up to 2.5 l. Furher increase of time did not affect the H2(g) production both under solar and visible light irradiation. This behavior is valid in the presence of 2 mg/l Ni-W-O nanocomposite with a Ni / W / O ratio of 0.8 / 0.5 / 0.2.

| Illumination time (min) | H2(g) production ( l ) |

| 20 | 0.800 |

| 30 | 1.000 |

| 40 | 1.870 |

| 50 | 2.000 |

| 60 | 2.300 |

| 70 | 2.500 |

| 80 | 2.670 |

| 120 | 2.000 |

Table 3. Effect of illumination time on H2(g) production efficiency

The efficiency of photocatalytic water splitting can be improved by increasing light intensity with energies more than the activation threshold. The variation of reaction rate as a function of wavelength comes after the adsorption spectrum of the catalyst with a threshold corresponding to the band energy. In this stuy the H2(g) production increased from 1 l up to 2.760 l when the UV ligth intensity was increased from 30 W/ m2 up to 90 W/m2 (Table 4). Further increase of UV power did not affect the H2(g) production. It was recorded that the photocatalytic hydrogen production using Ni-W-O showed 50% improved photoactivity by increasing light light intensity was increased.

| Ligth intensity (W/m2) | H2(g) production ( l ) |

| 20 | 0.800 |

| 30 | 1.000 |

| 40 | 1.870 |

| 50 | 2.000 |

| 60 | 2.300 |

| 70 | 2.500 |

| 80 | 2.600 |

| 90 | 2.760 |

| 100 | 2.000 |

| 110 | 2.000 |

Table 4. Effect of ligth intensity on H2(g) production efficiency

Thermodynamically, temperature cannot induce the photocatalysis activity, since it did not contribute toward the generation of electrons and holes. However, temperature plays a role to enhance desorption of products from the surface of catalyst to increase the photocatalytic activity. The temperature speeds up the reaction rate. The temperature applied differs for different catalyst. Therefore, this factor could quickly be adjusted to increase the photocatalytic activity. In this study as the temperature was increased from 20oC to 60oC the H2(g) production elevated from 0.600 l up to 2.700 l (Table 5). Reduce temperature gives negative effect by slowing the H2(g) production rate as desorption of the products limits the reaction, since it is slower the adsorption of the reactants. High temperature provides higher electron transfers in valance band to higher energy levels. Thus, it facilitates the electrone hole formation that could be utilized in initiating oxidation and reduction reactions, respectively, and helps the reaction to compete more effectively with charge carries recombination. It was reported that H2(g) evolution increased with temperature up to 70oC. Further increasing the temperature, however, seems to deteriorate the reaction rate. It was reported that the catalytic properties of these nanocomposite from the aspects of investigating the intrinsic catalytic properties, the number of active sites and metal–support interactions lpwered at very high temperatures.

| Temperature (oC) | H2(g) production ( l ) |

| 20 | 0.800 |

| 30 | 1.000 |

| 40 | 1.870 |

| 50 | 2.000 |

| 60 | 2.700 |

| 70 | 2.500 |

| 80 | 2.600 |

| 90 | 2.000 |

| 100 | 2.000 |

| 110 | 2.000 |

Table 5. Effect of increasing temperature on H2(g) production efficiency

It can be regarded that the production of H2(g) from water splitting is dependent upon the proton concentration, which is the pH of the solution, since proton reduction by the photogenerated electron is generated throughout water splitting. This specific aspect is particularly importance in the case of photo reforming as the presence of a sacrificial organic species. In this stuy the maximum H2(g) generation was detected at a pH of 8.0 (Table 6). Acidic and basic conditions decrease the H2(g) production. It was reported that Ni-W-O catalyst for H2(g) evolution depends on the pH of the mixture while the optimum pH is close to the zero-point charge. At acidic pH, more Hþ ions are adsorbed on the photo catalyst, so the possibility of the reduction of Hþ to H2 by e-1 will not increased. It was reported that in the photocatalytic reaction in low basic system gives more advantages to enhance H2(g) evolution.

| pH | H2(g) production ( l ) |

| 4 | 0.800 |

| 5 | 1.000 |

| 7 | 1.870 |

| 8 | 2.700 |

| 9 | 2.340 |

| 10 | 2000 |

| 11 | 1.000 |

| 12 | 0.400 |

Table 6. Effect of pH on H2(g) production efficiency

The metal oxide can be introduced to effect oxygen vacancies by catalyst synthesis, reduction and doping. For Ni-W-O nanocomposite the oxygen vacancies are existed along with Ni-W-O. When the oxygen vacancies concentration is higher, more ions are produced, thus causes a defect state, surface disorder and associate oxygen vacancies. Due to missing oxygen atom, the oxygen vacancies defect can trap and prolong the life of electrons. Whereas, the regular lattice of the oxygen atom was taken by electrons and local state was formed by oxygen vacancies in the Ni-W-O nanocatalyst. Then, the valens band holes of Ni-W-O were generated and the electrons excited to the conduction bant of the nanocomposite. As a result the electroneholes recombination enhanced the H2(g) production. In order to detect the effects of O2(g) concentration on H2(g) production via 2 mg/l Ni-W-O nanocomposite the dissolved oxygen concentration was increased from 0.5 mg/l up to 4 mg/l. The maximum H2(g) yields was tetected at 1.8 mg/l dissolved oxygen concentration ( 2.700 l )(Table 7).

| Dissolved oxygen concentration (mg/l) | H2(g) production ( l ) |

| 0 | 0.800 |

| 0.5 | 1.000 |

| 1.0 | 1.870 |

| 1.8 | 2.700 |

| 2.0 | 2.040 |

| 2.5 | 2.000 |

| 3.0 | 1.000 |

| 4.0 | 0.400 |

Table 7. Effect of dissolved oxygen on H2(g) production efficiency

The XRD pattern of the as-synthesized hydrothermal sample (Figure 1) resembles some features of that of NiWO4 but with significant peak broadening and diffuse scattering, indicating the formation of a poorly crystallized product. Further annealing this sample at elevated temperature (over 400°C) in air could help remove possible solvent residue, improve its crystallinity, promote crystallite growth, and result in a well-defined XRD pattern consistent with that of NiWO4 (JCPDS 15–0755). Because of the poor crystallinity nature of the as-synthesized hydrothermal sample, its phase assignment was further corroborated by the spectroscopic analyses. Reductive annealing the hydrothermal sample at various temperatures resulted in the formation of nanocomposite catalysts with varied phase compositions and structures. As shown in Figure 1, the 350°C-reduced sample showed a similar XRD pattern to that of the hydrothermal sample but with a new peak appearing at 2θ = 43.68°, matching well with the (111) peak of the Ni17W3 phase (JCPDS 65–4828). Upon increasing the annealing temperature to 400°C, this peak becomes intensified with a low-angle shift by 0.2°, which corresponds well to the (211) peak of the Ni4W phase (JCPDS 65–2673). Meanwhile, the diffraction peaks from the hydrothermal sample completely disappeared and were replaced by the characteristic peaks from the WO2 phase (JCPDS 32–1393). With further elevation of the annealing temperature to 600°C, WO2 was reduced to metal W (JCPDS 04–0806) but with the Ni4W phase still preserved.

| Temperature (oC) | H2(g) production ( l ) |

| 20 | 0.800 |

| 30 | 1.000 |

| 40 | 1.870 |

| 50 | 2.000 |

| 60 | 2.700 |

| 70 | 2.500 |

| 80 | 2.600 |

| 90 | 2.000 |

| 100 | 2.000 |

| 110 | 2.000 |

Table 5. Effect of increasing temperature on H2(g) production efficiency

It can be regarded that the production of H2(g) from water splitting is dependent upon the proton concentration, which is the pH of the solution, since proton reduction by the photogenerated electron is generated throughout water splitting. This specific aspect is particularly importance in the case of photo reforming as the presence of a sacrificial organic species. In this stuy the maximum H2(g) generation was detected at a pH of 8.0 (Table 6). Acidic and basic conditions decrease the H2(g) production. It was reported that Ni-W-O catalyst for H2(g) evolution depends on the pH of the mixture while the optimum pH is close to the zero-point charge. At acidic pH, more Hþ ions are adsorbed on the photo catalyst, so the possibility of the reduction of Hþ to H2 by e-1 will not increased. It was reported that in the photocatalytic reaction in low basic system gives more advantages to enhance H2(g) evolution.

| pH | H2(g) production ( l ) |

| 4 | 0.800 |

| 5 | 1.000 |

| 7 | 1.870 |

| 8 | 2.700 |

| 9 | 2.340 |

| 10 | 2000 |

| 11 | 1.000 |

| 12 | 0.400 |

Table 6. Effect of pH on H2(g) production efficiency

The metal oxide can be introduced to effect oxygen vacancies by catalyst synthesis, reduction and doping. For Ni-W-O nanocomposite the oxygen vacancies are existed along with Ni-W-O. When the oxygen vacancies concentration is higher, more ions are produced, thus causes a defect state, surface disorder and associate oxygen vacancies. Due to missing oxygen atom, the oxygen vacancies defect can trap and prolong the life of electrons. Whereas, the regular lattice of the oxygen atom was taken by electrons and local state was formed by oxygen vacancies in the Ni-W-O nanocatalyst. Then, the valens band holes of Ni-W-O were generated and the electrons excited to the conduction bant of the nanocomposite. As a result the electroneholes recombination enhanced the H2(g) production. In order to detect the effects of O2(g) concentration on H2(g) production via 2 mg/l Ni-W-O nanocomposite the dissolved oxygen concentration was increased from 0.5 mg/l up to 4 mg/l. The maximum H2(g) yields was tetected at 1.8 mg/l dissolved oxygen concentration ( 2.700 l )(Table 7).

| Dissolved oxygen concentration (mg/l) | H2(g) production ( l ) |

| 0 | 0.800 |

| 0.5 | 1.000 |

| 1.0 | 1.870 |

| 1.8 | 2.700 |

| 2.0 | 2.040 |

| 2.5 | 2.000 |

| 3.0 | 1.000 |

| 4.0 | 0.400 |

Table 7. Effect of dissolved oxygen on H2(g) production efficiency

The XRD pattern of the as-synthesized hydrothermal sample (Figure 1)

resembles some features of that of NiWO4 but with significant peak broadening and diffuse scattering, indicating the formation of a poorly crystallized product. Further annealing this sample at elevated temperature (over 400°C) in air could help remove possible solvent residue, improve its crystallinity, promote crystallite growth, and result in a well-defined XRD pattern consistent with that of NiWO4 (JCPDS 15–0755). Because of the poor crystallinity nature of the as-synthesized hydrothermal sample, its phase assignment was further corroborated by the spectroscopic analyses. Reductive annealing the hydrothermal sample at various temperatures resulted in the formation of nanocomposite catalysts with varied phase compositions and structures. As shown in Figure 1, the 350°C-reduced sample showed a similar XRD pattern to that of the hydrothermal sample but with a new peak appearing at 2θ = 43.68°, matching well with the (111) peak of the Ni17W3 phase (JCPDS 65–4828). Upon increasing the annealing temperature to 400°C, this peak becomes intensified with a low-angle shift by 0.2°, which corresponds well to the (211) peak of the Ni4W phase (JCPDS 65–2673). Meanwhile, the diffraction peaks from the hydrothermal sample completely disappeared and were replaced by the characteristic peaks from the WO2 phase (JCPDS 32–1393). With further elevation of the annealing temperature to 600°C, WO2 was reduced to metal W (JCPDS 04–0806) but with the Ni4W phase still preserved.

| Temperature (oC) | H2(g) production ( l ) |

| 20 | 0.800 |

| 30 | 1.000 |

| 40 | 1.870 |

| 50 | 2.000 |

| 60 | 2.700 |

| 70 | 2.500 |

| 80 | 2.600 |

| 90 | 2.000 |

| 100 | 2.000 |

| 110 | 2.000 |

Table 5. Effect of increasing temperature on H2(g) production efficiency

It can be regarded that the production of H2(g) from water splitting is dependent upon the proton concentration, which is the pH of the solution, since proton reduction by the photogenerated electron is generated throughout water splitting. This specific aspect is particularly importance in the case of photo reforming as the presence of a sacrificial organic species. In this stuy the maximum H2(g) generation was detected at a pH of 8.0 (Table 6). Acidic and basic conditions decrease the H2(g) production. It was reported that Ni-W-O catalyst for H2(g) evolution depends on the pH of the mixture while the optimum pH is close to the zero-point charge. At acidic pH, more Hþ ions are adsorbed on the photo catalyst, so the possibility of the reduction of Hþ to H2 by e-1 will not increased. It was reported that in the photocatalytic reaction in low basic system gives more advantages to enhance H2(g) evolution.

| pH | H2(g) production ( l ) |

| 4 | 0.800 |

| 5 | 1.000 |

| 7 | 1.870 |

| 8 | 2.700 |

| 9 | 2.340 |

| 10 | 2000 |

| 11 | 1.000 |

| 12 | 0.400 |

Table 6. Effect of pH on H2(g) production efficiency

The metal oxide can be introduced to effect oxygen vacancies by catalyst synthesis, reduction and doping. For Ni-W-O nanocomposite the oxygen vacancies are existed along with Ni-W-O. When the oxygen vacancies concentration is higher, more ions are produced, thus causes a defect state, surface disorder and associate oxygen vacancies. Due to missing oxygen atom, the oxygen vacancies defect can trap and prolong the life of electrons. Whereas, the regular lattice of the oxygen atom was taken by electrons and local state was formed by oxygen vacancies in the Ni-W-O nanocatalyst. Then, the valens band holes of Ni-W-O were generated and the electrons excited to the conduction bant of the nanocomposite. As a result the electroneholes recombination enhanced the H2(g) production. In order to detect the effects of O2(g) concentration on H2(g) production via 2 mg/l Ni-W-O nanocomposite the dissolved oxygen concentration was increased from 0.5 mg/l up to 4 mg/l. The maximum H2(g) yields was tetected at 1.8 mg/l dissolved oxygen concentration ( 2.700 l )(Table 7).

| Dissolved oxygen concentration (mg/l) | H2(g) production ( l ) |

| 0 | 0.800 |

| 0.5 | 1.000 |

| 1.0 | 1.870 |

| 1.8 | 2.700 |

| 2.0 | 2.040 |

| 2.5 | 2.000 |

| 3.0 | 1.000 |

| 4.0 | 0.400 |

Table 7. Effect of dissolved oxygen on H2(g) production efficiency

The XRD pattern of the as-synthesized hydrothermal sample (Figure 1) resembles some features of that of NiWO4 but with significant peak broadening and diffuse scattering, indicating the formation of a poorly crystallized product. Further annealing this sample at elevated temperature (over 400°C) in air could help remove possible solvent residue, improve its crystallinity, promote crystallite growth, and result in a well-defined XRD pattern consistent with that of NiWO4 (JCPDS 15–0755). Because of the poor crystallinity nature of the as-synthesized hydrothermal sample, its phase assignment was further corroborated by the spectroscopic analyses. Reductive annealing the hydrothermal sample at various temperatures resulted in the formation of nanocomposite catalysts with varied phase compositions and structures. As shown in Figure 1, the 350°C-reduced sample showed a similar XRD pattern to that of the hydrothermal sample but with a new peak appearing at 2θ = 43.68°, matching well with the (111) peak of the Ni17W3 phase (JCPDS 65–4828). Upon increasing the annealing temperature to 400°C, this peak becomes intensified with a low-angle shift by 0.2°, which corresponds well to the (211) peak of the Ni4W phase (JCPDS 65–2673). Meanwhile, the diffraction peaks from the hydrothermal sample completely disappeared and were replaced by the characteristic peaks from the WO2 phase (JCPDS 32–1393). With further elevation of the annealing temperature to 600°C, WO2 was reduced to metal W (JCPDS 04–0806) but with the Ni4W phase still preserved.

FTIR spectra of Ni-W-O nanocomposite

FTIR spectra of the hydrothermal sample exhibited an intense peak at 822 cm−1 corresponding to the stretching vibrations of Ni–W–O. \

Figure 2: FTIR spectra results

The Raman spectrum clearly showed a strong band at 883 cm−1, which should be ascribed to the stretching vibrational mode of terminal W=O bonds, consistent with the featured assembly of WO6 octahedra in the NiWO4 structure (Figure 3). IR bands at around 1650 and 3400 cm−1 in Figure 3 should be assigned to the OH bending and stretching vibrations of the adsorbed water molecules. The phase assignments of the 400- and 600°C-reduced samples were further supported by the Raman spectra (data not shown).

Phase structure evolution of the hydrothermal samples upon reductive annealing was further investigated by operating TEM in high-resolution and selected-area electron diffraction (SAED) modes. As shown in Figure 4a, 4b and 4c, the SAED patterns discern the evolutionary reduction of the small NiWO4 crystallites in the hydrothermal sample during the reductive annealing process, from the initial precipitation of Ni17W3 to the concurrent

formation of Ni4W and WO2, and further to the metallic Ni4W and W phases. The high-resolution TEM images reveal the microstructure and phase constitution of the reduced samples. In the 350 °C-reduced sample, the lattice fringes with interplanar distances of 0.207 and 0.245 nm could be assigned to the (111) plane of Ni17W3 and the (002) plane of NiWO4, respectively (Figure 4d). Similarly, the characteristic d-spacings from the crystalline Ni4W and WO2 nanoparticles were identified in the 400°C-reduced sample (Figure 4e and 4f).

Figure 4: TEM analysis results (TEM images size: 200 nm).

In an effort to determine how the Ni–W alloy phases distribute on the W containing substrates, we examined the reduced samples by high-angle annular dark-field scanning transmission electron microscopy in combination with energy X-ray dispersive spectroscopy (EDS) analysis. The Ni and W elemental distributions gradually change from the atomic dispersion to the segregated nanoclusters with increasing annealing temperature. For the 400°C-reduced sample, the segregation of Ni and W elements became detectable because of the formation of the distinct Ni4W and WO2 phases. Further increasing the annealing temperature to 600°C resulted in aggravated segregation Ni and W, owing to the formation of W and the particle growth and aggregation of Ni4W. A close examination of the samples by EDS line-scanning profile analysis (Figure 5a, 5b and 5c) suggested that the size of the Ni4W nanoparticles increased from around 15 to 30 nm upon elevation of the annealing temperature from 400 to 600°C.

Figure 5: EDS analysis results (EDS images size: 200 nm).

The chemical states of the constituent elements in the hydrothermal and reduced samples were also examined using the surface-sensitive XPS. As presented in Figure 6, the hydrothermal sample exhibited only Ni(II) and W(VI) signals. After the reductive annealing treatment, additional signals of metallic Ni0 were detected, and their intensities increase with increasing annealing temperature. Similarly, the W 4f spectra of the reduced samples clearly manifested the formation of W(IV) and W0 species upon reduction. These results were in accord with XRD, SAED, and HRTEM observations, supporting the evolutionary formation of Ni–W alloys and W-containing substrate phases during the reduction process. A close examination of the XPS spectra further found subtle but significant binding energy shifts of Ni0 and W0. Specifically, the BEs of Ni0 in the reduced samples were observed to negatively shift in comparison with the BE of pristine metal Ni at 853.3 eV. Meanwhile, the W0 in the reduced samples showed positive BE shifts relative to pure W (31.0 eV). These results clearly indicated the electron transfer from W to Ni as a consequence of Ni–W alloys formation. In addition, XPS analysis clearly detected Ni(II) and W(VI) signals throughout the reduced samples but with decreased intensities upon high-temperature annealing. These results, together with the XRD, Raman, and HRTEM characterizations (Figure 6a, and 6b), suggested the presence of NiWO4 and WO3–x amorphous phases in the reduced samples. On the basis of the combination of phase, microstructure, and chemical state analyses, the resulting nanocatalysts from reductive annealing of the NiWO4 precursor at different temperatures were denoted as Ni17W3/NiWO4 (350°C), Ni4W/WO2/NiWO4 (400°C), and Ni4W/W/WO3–x (600 °C), respectively

Figure 6a: XPS analysis in Ni+2 samples

Figure 6b: XPS spectra in W+6 samples

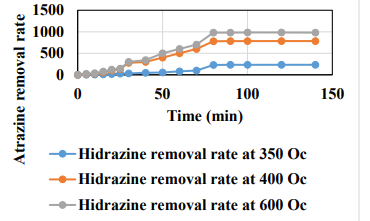

Previous studies illustrated that different initial adsorption conformations of N2H4 over metal surfaces can lead to distinct reaction pathways. In the case of only one N atom of N2H4 bonded to the metal surfaces, N–H bond cleavage of N2H4 molecules is energetically more favorable than N–N bond cleavage, which preferably results in H2(g) production. In contrast, the adsorption conformation with both N atoms of N2H4 bonding to the surfaces dominantly leads to NH3 formation. Hence, the adsorption energy difference between one-N-atom and two-N-atom conformations can serve as an indicator to evaluate the reaction selectivity of N2H4 decomposition. According to the DFT calculation results, the adsorption energy difference on the Ni4W surface is larger than that on the Ni17W3 surface by nearly a factor of 2, implying a significantly higher H2(g) selectivity for Ni4W. This is in good accordance with the experimental results. Therefore, it can be concluded that the improved catalytic performance of the Ni–W–O-derived catalysts upon increasing the annealing temperature from 350 to 400°C should stem from the resultant Ni4W with higher intrinsic activity and H2(g) selectivity than Ni17W3. The reaction rate of the system rapidly reached its maximum [90 ml (N2 + H2) min−1] within ~1 min and maintained at a level of ~80 ml (N2 + H2) min−1 for over 80 min (Figure 7).

The Ni–W–O-derived nanocomposite catalysts can be readily synthesized under laboratory conditions. The prepared catalysts exhibited remarkably distinct catalytic performances toward N2H4.H2O decomposition regarding H2(g) production. Using this noble-metal-free catalyst, decomposition of N2H4.H2O to hydrogen production was performed. For maximum photodegradation of hydrazine monohydrate to H2(g) the optimum operatinal conditions can be summarized as follws: Ni–W–O nanocomposite concentration of 2 mg/l with a Ni/W/O ratio of 0.8 / 0.5 / 0.2, 80 min irradiation time, a ligth power of 90 W/m2, a temperature of 60oC and a pH of 8.0. XRD, FTIR patterns, TEM images and UV−vis spectra of the catalyst exhibited the performances of noble-metal-free catalysts to produce efficiently H2(g) from N2H4.H2O. With this nanocomposite catalyst may produce H2(g) as fuel source.

This research study was undertaken in the Environmental Microbiology Laboratories at Dokuz Eylül University Engineering Faculty Environmental Engineering Department, Izmir, Turkey. The authors would like to thank this body for providing financial support.

Clearly Auctoresonline and particularly Psychology and Mental Health Care Journal is dedicated to improving health care services for individuals and populations. The editorial boards' ability to efficiently recognize and share the global importance of health literacy with a variety of stakeholders. Auctoresonline publishing platform can be used to facilitate of optimal client-based services and should be added to health care professionals' repertoire of evidence-based health care resources.

Journal of Clinical Cardiology and Cardiovascular Intervention The submission and review process was adequate. However I think that the publication total value should have been enlightened in early fases. Thank you for all.

Journal of Women Health Care and Issues By the present mail, I want to say thank to you and tour colleagues for facilitating my published article. Specially thank you for the peer review process, support from the editorial office. I appreciate positively the quality of your journal.

Journal of Clinical Research and Reports I would be very delighted to submit my testimonial regarding the reviewer board and the editorial office. The reviewer board were accurate and helpful regarding any modifications for my manuscript. And the editorial office were very helpful and supportive in contacting and monitoring with any update and offering help. It was my pleasure to contribute with your promising Journal and I am looking forward for more collaboration.

We would like to thank the Journal of Thoracic Disease and Cardiothoracic Surgery because of the services they provided us for our articles. The peer-review process was done in a very excellent time manner, and the opinions of the reviewers helped us to improve our manuscript further. The editorial office had an outstanding correspondence with us and guided us in many ways. During a hard time of the pandemic that is affecting every one of us tremendously, the editorial office helped us make everything easier for publishing scientific work. Hope for a more scientific relationship with your Journal.

The peer-review process which consisted high quality queries on the paper. I did answer six reviewers’ questions and comments before the paper was accepted. The support from the editorial office is excellent.

Journal of Neuroscience and Neurological Surgery. I had the experience of publishing a research article recently. The whole process was simple from submission to publication. The reviewers made specific and valuable recommendations and corrections that improved the quality of my publication. I strongly recommend this Journal.

Dr. Katarzyna Byczkowska My testimonial covering: "The peer review process is quick and effective. The support from the editorial office is very professional and friendly. Quality of the Clinical Cardiology and Cardiovascular Interventions is scientific and publishes ground-breaking research on cardiology that is useful for other professionals in the field.

Thank you most sincerely, with regard to the support you have given in relation to the reviewing process and the processing of my article entitled "Large Cell Neuroendocrine Carcinoma of The Prostate Gland: A Review and Update" for publication in your esteemed Journal, Journal of Cancer Research and Cellular Therapeutics". The editorial team has been very supportive.

Testimony of Journal of Clinical Otorhinolaryngology: work with your Reviews has been a educational and constructive experience. The editorial office were very helpful and supportive. It was a pleasure to contribute to your Journal.

Dr. Bernard Terkimbi Utoo, I am happy to publish my scientific work in Journal of Women Health Care and Issues (JWHCI). The manuscript submission was seamless and peer review process was top notch. I was amazed that 4 reviewers worked on the manuscript which made it a highly technical, standard and excellent quality paper. I appreciate the format and consideration for the APC as well as the speed of publication. It is my pleasure to continue with this scientific relationship with the esteem JWHCI.

This is an acknowledgment for peer reviewers, editorial board of Journal of Clinical Research and Reports. They show a lot of consideration for us as publishers for our research article “Evaluation of the different factors associated with side effects of COVID-19 vaccination on medical students, Mutah university, Al-Karak, Jordan”, in a very professional and easy way. This journal is one of outstanding medical journal.

Dear Hao Jiang, to Journal of Nutrition and Food Processing We greatly appreciate the efficient, professional and rapid processing of our paper by your team. If there is anything else we should do, please do not hesitate to let us know. On behalf of my co-authors, we would like to express our great appreciation to editor and reviewers.

As an author who has recently published in the journal "Brain and Neurological Disorders". I am delighted to provide a testimonial on the peer review process, editorial office support, and the overall quality of the journal. The peer review process at Brain and Neurological Disorders is rigorous and meticulous, ensuring that only high-quality, evidence-based research is published. The reviewers are experts in their fields, and their comments and suggestions were constructive and helped improve the quality of my manuscript. The review process was timely and efficient, with clear communication from the editorial office at each stage. The support from the editorial office was exceptional throughout the entire process. The editorial staff was responsive, professional, and always willing to help. They provided valuable guidance on formatting, structure, and ethical considerations, making the submission process seamless. Moreover, they kept me informed about the status of my manuscript and provided timely updates, which made the process less stressful. The journal Brain and Neurological Disorders is of the highest quality, with a strong focus on publishing cutting-edge research in the field of neurology. The articles published in this journal are well-researched, rigorously peer-reviewed, and written by experts in the field. The journal maintains high standards, ensuring that readers are provided with the most up-to-date and reliable information on brain and neurological disorders. In conclusion, I had a wonderful experience publishing in Brain and Neurological Disorders. The peer review process was thorough, the editorial office provided exceptional support, and the journal's quality is second to none. I would highly recommend this journal to any researcher working in the field of neurology and brain disorders.

Dear Agrippa Hilda, Journal of Neuroscience and Neurological Surgery, Editorial Coordinator, I trust this message finds you well. I want to extend my appreciation for considering my article for publication in your esteemed journal. I am pleased to provide a testimonial regarding the peer review process and the support received from your editorial office. The peer review process for my paper was carried out in a highly professional and thorough manner. The feedback and comments provided by the authors were constructive and very useful in improving the quality of the manuscript. This rigorous assessment process undoubtedly contributes to the high standards maintained by your journal.

International Journal of Clinical Case Reports and Reviews. I strongly recommend to consider submitting your work to this high-quality journal. The support and availability of the Editorial staff is outstanding and the review process was both efficient and rigorous.

Thank you very much for publishing my Research Article titled “Comparing Treatment Outcome Of Allergic Rhinitis Patients After Using Fluticasone Nasal Spray And Nasal Douching" in the Journal of Clinical Otorhinolaryngology. As Medical Professionals we are immensely benefited from study of various informative Articles and Papers published in this high quality Journal. I look forward to enriching my knowledge by regular study of the Journal and contribute my future work in the field of ENT through the Journal for use by the medical fraternity. The support from the Editorial office was excellent and very prompt. I also welcome the comments received from the readers of my Research Article.

Dear Erica Kelsey, Editorial Coordinator of Cancer Research and Cellular Therapeutics Our team is very satisfied with the processing of our paper by your journal. That was fast, efficient, rigorous, but without unnecessary complications. We appreciated the very short time between the submission of the paper and its publication on line on your site.

I am very glad to say that the peer review process is very successful and fast and support from the Editorial Office. Therefore, I would like to continue our scientific relationship for a long time. And I especially thank you for your kindly attention towards my article. Have a good day!

"We recently published an article entitled “Influence of beta-Cyclodextrins upon the Degradation of Carbofuran Derivatives under Alkaline Conditions" in the Journal of “Pesticides and Biofertilizers” to show that the cyclodextrins protect the carbamates increasing their half-life time in the presence of basic conditions This will be very helpful to understand carbofuran behaviour in the analytical, agro-environmental and food areas. We greatly appreciated the interaction with the editor and the editorial team; we were particularly well accompanied during the course of the revision process, since all various steps towards publication were short and without delay".

I would like to express my gratitude towards you process of article review and submission. I found this to be very fair and expedient. Your follow up has been excellent. I have many publications in national and international journal and your process has been one of the best so far. Keep up the great work.

We are grateful for this opportunity to provide a glowing recommendation to the Journal of Psychiatry and Psychotherapy. We found that the editorial team were very supportive, helpful, kept us abreast of timelines and over all very professional in nature. The peer review process was rigorous, efficient and constructive that really enhanced our article submission. The experience with this journal remains one of our best ever and we look forward to providing future submissions in the near future.

I am very pleased to serve as EBM of the journal, I hope many years of my experience in stem cells can help the journal from one way or another. As we know, stem cells hold great potential for regenerative medicine, which are mostly used to promote the repair response of diseased, dysfunctional or injured tissue using stem cells or their derivatives. I think Stem Cell Research and Therapeutics International is a great platform to publish and share the understanding towards the biology and translational or clinical application of stem cells.

I would like to give my testimony in the support I have got by the peer review process and to support the editorial office where they were of asset to support young author like me to be encouraged to publish their work in your respected journal and globalize and share knowledge across the globe. I really give my great gratitude to your journal and the peer review including the editorial office.

I am delighted to publish our manuscript entitled "A Perspective on Cocaine Induced Stroke - Its Mechanisms and Management" in the Journal of Neuroscience and Neurological Surgery. The peer review process, support from the editorial office, and quality of the journal are excellent. The manuscripts published are of high quality and of excellent scientific value. I recommend this journal very much to colleagues.

Dr.Tania Muñoz, My experience as researcher and author of a review article in The Journal Clinical Cardiology and Interventions has been very enriching and stimulating. The editorial team is excellent, performs its work with absolute responsibility and delivery. They are proactive, dynamic and receptive to all proposals. Supporting at all times the vast universe of authors who choose them as an option for publication. The team of review specialists, members of the editorial board, are brilliant professionals, with remarkable performance in medical research and scientific methodology. Together they form a frontline team that consolidates the JCCI as a magnificent option for the publication and review of high-level medical articles and broad collective interest. I am honored to be able to share my review article and open to receive all your comments.

“The peer review process of JPMHC is quick and effective. Authors are benefited by good and professional reviewers with huge experience in the field of psychology and mental health. The support from the editorial office is very professional. People to contact to are friendly and happy to help and assist any query authors might have. Quality of the Journal is scientific and publishes ground-breaking research on mental health that is useful for other professionals in the field”.

Dear editorial department: On behalf of our team, I hereby certify the reliability and superiority of the International Journal of Clinical Case Reports and Reviews in the peer review process, editorial support, and journal quality. Firstly, the peer review process of the International Journal of Clinical Case Reports and Reviews is rigorous, fair, transparent, fast, and of high quality. The editorial department invites experts from relevant fields as anonymous reviewers to review all submitted manuscripts. These experts have rich academic backgrounds and experience, and can accurately evaluate the academic quality, originality, and suitability of manuscripts. The editorial department is committed to ensuring the rigor of the peer review process, while also making every effort to ensure a fast review cycle to meet the needs of authors and the academic community. Secondly, the editorial team of the International Journal of Clinical Case Reports and Reviews is composed of a group of senior scholars and professionals with rich experience and professional knowledge in related fields. The editorial department is committed to assisting authors in improving their manuscripts, ensuring their academic accuracy, clarity, and completeness. Editors actively collaborate with authors, providing useful suggestions and feedback to promote the improvement and development of the manuscript. We believe that the support of the editorial department is one of the key factors in ensuring the quality of the journal. Finally, the International Journal of Clinical Case Reports and Reviews is renowned for its high- quality articles and strict academic standards. The editorial department is committed to publishing innovative and academically valuable research results to promote the development and progress of related fields. The International Journal of Clinical Case Reports and Reviews is reasonably priced and ensures excellent service and quality ratio, allowing authors to obtain high-level academic publishing opportunities in an affordable manner. I hereby solemnly declare that the International Journal of Clinical Case Reports and Reviews has a high level of credibility and superiority in terms of peer review process, editorial support, reasonable fees, and journal quality. Sincerely, Rui Tao.

Clinical Cardiology and Cardiovascular Interventions I testity the covering of the peer review process, support from the editorial office, and quality of the journal.

Clinical Cardiology and Cardiovascular Interventions, we deeply appreciate the interest shown in our work and its publication. It has been a true pleasure to collaborate with you. The peer review process, as well as the support provided by the editorial office, have been exceptional, and the quality of the journal is very high, which was a determining factor in our decision to publish with you.

The peer reviewers process is quick and effective, the supports from editorial office is excellent, the quality of journal is high. I would like to collabroate with Internatioanl journal of Clinical Case Reports and Reviews journal clinically in the future time.

Clinical Cardiology and Cardiovascular Interventions, I would like to express my sincerest gratitude for the trust placed in our team for the publication in your journal. It has been a true pleasure to collaborate with you on this project. I am pleased to inform you that both the peer review process and the attention from the editorial coordination have been excellent. Your team has worked with dedication and professionalism to ensure that your publication meets the highest standards of quality. We are confident that this collaboration will result in mutual success, and we are eager to see the fruits of this shared effort.

Dear Dr. Jessica Magne, Editorial Coordinator 0f Clinical Cardiology and Cardiovascular Interventions, I hope this message finds you well. I want to express my utmost gratitude for your excellent work and for the dedication and speed in the publication process of my article titled "Navigating Innovation: Qualitative Insights on Using Technology for Health Education in Acute Coronary Syndrome Patients." I am very satisfied with the peer review process, the support from the editorial office, and the quality of the journal. I hope we can maintain our scientific relationship in the long term.

Dear Monica Gissare, - Editorial Coordinator of Nutrition and Food Processing. ¨My testimony with you is truly professional, with a positive response regarding the follow-up of the article and its review, you took into account my qualities and the importance of the topic¨.

Dear Dr. Jessica Magne, Editorial Coordinator 0f Clinical Cardiology and Cardiovascular Interventions, The review process for the article “The Handling of Anti-aggregants and Anticoagulants in the Oncologic Heart Patient Submitted to Surgery” was extremely rigorous and detailed. From the initial submission to the final acceptance, the editorial team at the “Journal of Clinical Cardiology and Cardiovascular Interventions” demonstrated a high level of professionalism and dedication. The reviewers provided constructive and detailed feedback, which was essential for improving the quality of our work. Communication was always clear and efficient, ensuring that all our questions were promptly addressed. The quality of the “Journal of Clinical Cardiology and Cardiovascular Interventions” is undeniable. It is a peer-reviewed, open-access publication dedicated exclusively to disseminating high-quality research in the field of clinical cardiology and cardiovascular interventions. The journal's impact factor is currently under evaluation, and it is indexed in reputable databases, which further reinforces its credibility and relevance in the scientific field. I highly recommend this journal to researchers looking for a reputable platform to publish their studies.

Dear Editorial Coordinator of the Journal of Nutrition and Food Processing! "I would like to thank the Journal of Nutrition and Food Processing for including and publishing my article. The peer review process was very quick, movement and precise. The Editorial Board has done an extremely conscientious job with much help, valuable comments and advices. I find the journal very valuable from a professional point of view, thank you very much for allowing me to be part of it and I would like to participate in the future!”

Dealing with The Journal of Neurology and Neurological Surgery was very smooth and comprehensive. The office staff took time to address my needs and the response from editors and the office was prompt and fair. I certainly hope to publish with this journal again.Their professionalism is apparent and more than satisfactory. Susan Weiner

My Testimonial Covering as fellowing: Lin-Show Chin. The peer reviewers process is quick and effective, the supports from editorial office is excellent, the quality of journal is high. I would like to collabroate with Internatioanl journal of Clinical Case Reports and Reviews.

My experience publishing in Psychology and Mental Health Care was exceptional. The peer review process was rigorous and constructive, with reviewers providing valuable insights that helped enhance the quality of our work. The editorial team was highly supportive and responsive, making the submission process smooth and efficient. The journal's commitment to high standards and academic rigor makes it a respected platform for quality research. I am grateful for the opportunity to publish in such a reputable journal.

My experience publishing in International Journal of Clinical Case Reports and Reviews was exceptional. I Come forth to Provide a Testimonial Covering the Peer Review Process and the editorial office for the Professional and Impartial Evaluation of the Manuscript.

I would like to offer my testimony in the support. I have received through the peer review process and support the editorial office where they are to support young authors like me, encourage them to publish their work in your esteemed journals, and globalize and share knowledge globally. I really appreciate your journal, peer review, and editorial office.

Dear Agrippa Hilda- Editorial Coordinator of Journal of Neuroscience and Neurological Surgery, "The peer review process was very quick and of high quality, which can also be seen in the articles in the journal. The collaboration with the editorial office was very good."

I would like to express my sincere gratitude for the support and efficiency provided by the editorial office throughout the publication process of my article, “Delayed Vulvar Metastases from Rectal Carcinoma: A Case Report.” I greatly appreciate the assistance and guidance I received from your team, which made the entire process smooth and efficient. The peer review process was thorough and constructive, contributing to the overall quality of the final article. I am very grateful for the high level of professionalism and commitment shown by the editorial staff, and I look forward to maintaining a long-term collaboration with the International Journal of Clinical Case Reports and Reviews.

To Dear Erin Aust, I would like to express my heartfelt appreciation for the opportunity to have my work published in this esteemed journal. The entire publication process was smooth and well-organized, and I am extremely satisfied with the final result. The Editorial Team demonstrated the utmost professionalism, providing prompt and insightful feedback throughout the review process. Their clear communication and constructive suggestions were invaluable in enhancing my manuscript, and their meticulous attention to detail and dedication to quality are truly commendable. Additionally, the support from the Editorial Office was exceptional. From the initial submission to the final publication, I was guided through every step of the process with great care and professionalism. The team's responsiveness and assistance made the entire experience both easy and stress-free. I am also deeply impressed by the quality and reputation of the journal. It is an honor to have my research featured in such a respected publication, and I am confident that it will make a meaningful contribution to the field.

"I am grateful for the opportunity of contributing to [International Journal of Clinical Case Reports and Reviews] and for the rigorous review process that enhances the quality of research published in your esteemed journal. I sincerely appreciate the time and effort of your team who have dedicatedly helped me in improvising changes and modifying my manuscript. The insightful comments and constructive feedback provided have been invaluable in refining and strengthening my work".

I thank the ‘Journal of Clinical Research and Reports’ for accepting this article for publication. This is a rigorously peer reviewed journal which is on all major global scientific data bases. I note the review process was prompt, thorough and professionally critical. It gave us an insight into a number of important scientific/statistical issues. The review prompted us to review the relevant literature again and look at the limitations of the study. The peer reviewers were open, clear in the instructions and the editorial team was very prompt in their communication. This journal certainly publishes quality research articles. I would recommend the journal for any future publications.

Dear Jessica Magne, with gratitude for the joint work. Fast process of receiving and processing the submitted scientific materials in “Clinical Cardiology and Cardiovascular Interventions”. High level of competence of the editors with clear and correct recommendations and ideas for enriching the article.

We found the peer review process quick and positive in its input. The support from the editorial officer has been very agile, always with the intention of improving the article and taking into account our subsequent corrections.

My article, titled 'No Way Out of the Smartphone Epidemic Without Considering the Insights of Brain Research,' has been republished in the International Journal of Clinical Case Reports and Reviews. The review process was seamless and professional, with the editors being both friendly and supportive. I am deeply grateful for their efforts.

To Dear Erin Aust – Editorial Coordinator of Journal of General Medicine and Clinical Practice! I declare that I am absolutely satisfied with your work carried out with great competence in following the manuscript during the various stages from its receipt, during the revision process to the final acceptance for publication. Thank Prof. Elvira Farina

Dear Jessica, and the super professional team of the ‘Clinical Cardiology and Cardiovascular Interventions’ I am sincerely grateful to the coordinated work of the journal team for the no problem with the submission of my manuscript: “Cardiometabolic Disorders in A Pregnant Woman with Severe Preeclampsia on the Background of Morbid Obesity (Case Report).” The review process by 5 experts was fast, and the comments were professional, which made it more specific and academic, and the process of publication and presentation of the article was excellent. I recommend that my colleagues publish articles in this journal, and I am interested in further scientific cooperation. Sincerely and best wishes, Dr. Oleg Golyanovskiy.

Dear Ashley Rosa, Editorial Coordinator of the journal - Psychology and Mental Health Care. " The process of obtaining publication of my article in the Psychology and Mental Health Journal was positive in all areas. The peer review process resulted in a number of valuable comments, the editorial process was collaborative and timely, and the quality of this journal has been quickly noticed, resulting in alternative journals contacting me to publish with them." Warm regards, Susan Anne Smith, PhD. Australian Breastfeeding Association.

Dear Jessica Magne, Editorial Coordinator, Clinical Cardiology and Cardiovascular Interventions, Auctores Publishing LLC. I appreciate the journal (JCCI) editorial office support, the entire team leads were always ready to help, not only on technical front but also on thorough process. Also, I should thank dear reviewers’ attention to detail and creative approach to teach me and bring new insights by their comments. Surely, more discussions and introduction of other hemodynamic devices would provide better prevention and management of shock states. Your efforts and dedication in presenting educational materials in this journal are commendable. Best wishes from, Farahnaz Fallahian.

Dear Maria Emerson, Editorial Coordinator, International Journal of Clinical Case Reports and Reviews, Auctores Publishing LLC. I am delighted to have published our manuscript, "Acute Colonic Pseudo-Obstruction (ACPO): A rare but serious complication following caesarean section." I want to thank the editorial team, especially Maria Emerson, for their prompt review of the manuscript, quick responses to queries, and overall support. Yours sincerely Dr. Victor Olagundoye.

Dear Ashley Rosa, Editorial Coordinator, International Journal of Clinical Case Reports and Reviews. Many thanks for publishing this manuscript after I lost confidence the editors were most helpful, more than other journals Best wishes from, Susan Anne Smith, PhD. Australian Breastfeeding Association.

Dear Agrippa Hilda, Editorial Coordinator, Journal of Neuroscience and Neurological Surgery. The entire process including article submission, review, revision, and publication was extremely easy. The journal editor was prompt and helpful, and the reviewers contributed to the quality of the paper. Thank you so much! Eric Nussbaum, MD

Dr Hala Al Shaikh This is to acknowledge that the peer review process for the article ’ A Novel Gnrh1 Gene Mutation in Four Omani Male Siblings, Presentation and Management ’ sent to the International Journal of Clinical Case Reports and Reviews was quick and smooth. The editorial office was prompt with easy communication.

Dear Erin Aust, Editorial Coordinator, Journal of General Medicine and Clinical Practice. We are pleased to share our experience with the “Journal of General Medicine and Clinical Practice”, following the successful publication of our article. The peer review process was thorough and constructive, helping to improve the clarity and quality of the manuscript. We are especially thankful to Ms. Erin Aust, the Editorial Coordinator, for her prompt communication and continuous support throughout the process. Her professionalism ensured a smooth and efficient publication experience. The journal upholds high editorial standards, and we highly recommend it to fellow researchers seeking a credible platform for their work. Best wishes By, Dr. Rakhi Mishra.

Dear Jessica Magne, Editorial Coordinator, Clinical Cardiology and Cardiovascular Interventions, Auctores Publishing LLC. The peer review process of the journal of Clinical Cardiology and Cardiovascular Interventions was excellent and fast, as was the support of the editorial office and the quality of the journal. Kind regards Walter F. Riesen Prof. Dr. Dr. h.c. Walter F. Riesen.

Dear Ashley Rosa, Editorial Coordinator, International Journal of Clinical Case Reports and Reviews, Auctores Publishing LLC. Thank you for publishing our article, Exploring Clozapine's Efficacy in Managing Aggression: A Multiple Single-Case Study in Forensic Psychiatry in the international journal of clinical case reports and reviews. We found the peer review process very professional and efficient. The comments were constructive, and the whole process was efficient. On behalf of the co-authors, I would like to thank you for publishing this article. With regards, Dr. Jelle R. Lettinga.

Dear Clarissa Eric, Editorial Coordinator, Journal of Clinical Case Reports and Studies, I would like to express my deep admiration for the exceptional professionalism demonstrated by your journal. I am thoroughly impressed by the speed of the editorial process, the substantive and insightful reviews, and the meticulous preparation of the manuscript for publication. Additionally, I greatly appreciate the courteous and immediate responses from your editorial office to all my inquiries. Best Regards, Dariusz Ziora

Dear Chrystine Mejia, Editorial Coordinator, Journal of Neurodegeneration and Neurorehabilitation, Auctores Publishing LLC, We would like to thank the editorial team for the smooth and high-quality communication leading up to the publication of our article in the Journal of Neurodegeneration and Neurorehabilitation. The reviewers have extensive knowledge in the field, and their relevant questions helped to add value to our publication. Kind regards, Dr. Ravi Shrivastava.

Dear Clarissa Eric, Editorial Coordinator, Journal of Clinical Case Reports and Studies, Auctores Publishing LLC, USA Office: +1-(302)-520-2644. I would like to express my sincere appreciation for the efficient and professional handling of my case report by the ‘Journal of Clinical Case Reports and Studies’. The peer review process was not only fast but also highly constructive—the reviewers’ comments were clear, relevant, and greatly helped me improve the quality and clarity of my manuscript. I also received excellent support from the editorial office throughout the process. Communication was smooth and timely, and I felt well guided at every stage, from submission to publication. The overall quality and rigor of the journal are truly commendable. I am pleased to have published my work with Journal of Clinical Case Reports and Studies, and I look forward to future opportunities for collaboration. Sincerely, Aline Tollet, UCLouvain.

Dear Ms. Mayra Duenas, Editorial Coordinator, International Journal of Clinical Case Reports and Reviews. “The International Journal of Clinical Case Reports and Reviews represented the “ideal house” to share with the research community a first experience with the use of the Simeox device for speech rehabilitation. High scientific reputation and attractive website communication were first determinants for the selection of this Journal, and the following submission process exceeded expectations: fast but highly professional peer review, great support by the editorial office, elegant graphic layout. Exactly what a dynamic research team - also composed by allied professionals - needs!" From, Chiara Beccaluva, PT - Italy.

Dear Maria Emerson, Editorial Coordinator, we have deeply appreciated the professionalism demonstrated by the International Journal of Clinical Case Reports and Reviews. The reviewers have extensive knowledge of our field and have been very efficient and fast in supporting the process. I am really looking forward to further collaboration. Thanks. Best regards, Dr. Claudio Ligresti

Dear Chrystine Mejia, Editorial Coordinator, Journal of Neurodegeneration and Neurorehabilitation. “The peer review process was efficient and constructive, and the editorial office provided excellent communication and support throughout. The journal ensures scientific rigor and high editorial standards, while also offering a smooth and timely publication process. We sincerely appreciate the work of the editorial team in facilitating the dissemination of innovative approaches such as the Bonori Method.” Best regards, Dr. Matteo Bonori.

I recommend without hesitation submitting relevant papers on medical decision making to the International Journal of Clinical Case Reports and Reviews. I am very grateful to the editorial staff. Maria Emerson was a pleasure to communicate with. The time from submission to publication was an extremely short 3 weeks. The editorial staff submitted the paper to three reviewers. Two of the reviewers commented positively on the value of publishing the paper. The editorial staff quickly recognized the third reviewer’s comments as an unjust attempt to reject the paper. I revised the paper as recommended by the first two reviewers.

Dear Maria Emerson, Editorial Coordinator, Journal of Clinical Research and Reports. Thank you for publishing our case report: "Clinical Case of Effective Fetal Stem Cells Treatment in a Patient with Autism Spectrum Disorder" within the "Journal of Clinical Research and Reports" being submitted by the team of EmCell doctors from Kyiv, Ukraine. We much appreciate a professional and transparent peer-review process from Auctores. All research Doctors are so grateful to your Editorial Office and Auctores Publishing support! I amiably wish our article publication maintained a top quality of your International Scientific Journal. My best wishes for a prosperity of the Journal of Clinical Research and Reports. Hope our scientific relationship and cooperation will remain long lasting. Thank you very much indeed. Kind regards, Dr. Andriy Sinelnyk Cell Therapy Center EmCell

Dear Editorial Team, Clinical Cardiology and Cardiovascular Interventions. It was truly a rewarding experience to work with the journal “Clinical Cardiology and Cardiovascular Interventions”. The peer review process was insightful and encouraging, helping us refine our work to a higher standard. The editorial office offered exceptional support with prompt and thoughtful communication. I highly value the journal’s role in promoting scientific advancement and am honored to be part of it. Best regards, Meng-Jou Lee, MD, Department of Anesthesiology, National Taiwan University Hospital.

Dear Editorial Team, Journal-Clinical Cardiology and Cardiovascular Interventions, “Publishing my article with Clinical Cardiology and Cardiovascular Interventions has been a highly positive experience. The peer-review process was rigorous yet supportive, offering valuable feedback that strengthened my work. The editorial team demonstrated exceptional professionalism, prompt communication, and a genuine commitment to maintaining the highest scientific standards. I am very pleased with the publication quality and proud to be associated with such a reputable journal.” Warm regards, Dr. Mahmoud Kamal Moustafa Ahmed

Dear Maria Emerson, Editorial Coordinator of ‘International Journal of Clinical Case Reports and Reviews’, I appreciate the opportunity to publish my article with your journal. The editorial office provided clear communication during the submission and review process, and I found the overall experience professional and constructive. Best regards, Elena Salvatore.

Dear Mayra Duenas, Editorial Coordinator of ‘International Journal of Clinical Case Reports and Reviews Herewith I confirm an optimal peer review process and a great support of the editorial office of the present journal

Dear Editorial Team, Clinical Cardiology and Cardiovascular Interventions. I am really grateful for the peers review; their feedback gave me the opportunity to reflect on the message and impact of my work and to ameliorate the article. The editors did a great job in addition by encouraging me to continue with the process of publishing.

Dear Cecilia Lilly, Editorial Coordinator, Endocrinology and Disorders, Thank you so much for your quick response regarding reviewing and all process till publishing our manuscript entitled: Prevalence of Pre-Diabetes and its Associated Risk Factors Among Nile College Students, Sudan. Best regards, Dr Mamoun Magzoub.

International Journal of Clinical Case Reports and Reviews is a high quality journal that has a clear and concise submission process. The peer review process was comprehensive and constructive. Support from the editorial office was excellent, since the administrative staff were responsive. The journal provides a fast and timely publication timeline.

Dear Maria Emerson, Editorial Coordinator of International Journal of Clinical Case Reports and Reviews, What distinguishes International Journal of Clinical Case Report and Review is not only the scientific rigor of its publications, but the intellectual climate in which research is evaluated. The submission process is refreshingly free of unnecessary formal barriers and bureaucratic rituals that often complicate academic publishing without adding real value. The peer-review system is demanding yet constructive, guided by genuine scientific dialogue rather than hierarchical or authoritarian attitudes. Reviewers act as collaborators in improving the manuscript, not as gatekeepers imposing arbitrary standards. This journal offers a rare balance: high methodological standards combined with a respectful, transparent, and supportive editorial approach. In an era where publishing can feel more burdensome than research itself, this platform restores the original purpose of peer review — to refine ideas, not to obstruct them Prof. Perlat Kapisyzi, FCCP PULMONOLOGIST AND THORACIC IMAGING.

Dear Grace Pierce, International Journal of Clinical Case Reports and Reviews I appreciate the opportunity to review for Auctore Journal, as the overall editorial process was smooth, transparent and professionally managed. This journal maintains high scientific standards and ensures timely communications with authors, which is truly commendable. I would like to express my special thanks to editor Grace Pierce for his constant guidance, promt responses, and supportive coordination throughout the review process. I am also greatful to Eleanor Bailey from the finance department for her clear communication and efficient handling of all administrative matters. Overall, my experience with Auctore Journal has been highly positive and rewarding. Best regards, Sabita sinha

Dear Mayra Duenas, Editorial Coordinator of the journal IJCCR, I write here a little on my experience as an author submitting to the International Journal of Clinical Case Reports and Reviews (IJCCR). This was my first submission to IJCCR and my manuscript was inherently an outsider’s effort. It attempted to broadly identify and then make some sense of life’s under-appreciated mysteries. I initially had responded to a request for possible submissions. I then contacted IJCCR with a tentative topic for a manuscript. They quickly got back with an approval for the submission, but with a particular requirement that it be medically relevant. I then put together a manuscript and submitted it. After the usual back-and-forth over forms and formality, the manuscript was sent off for reviews. Within 2 weeks I got back 4 reviews which were both helpful and also surprising. Surprising in that the topic was somewhat foreign to medical literature. My subsequent updates in response to the reviewer comments went smoothly and in short order I had a series of proofs to evaluate. All in all, the whole publication process seemed outstanding. It was both helpful in terms of the paper’s content and also in terms of its efficient and friendly communications. Thank you all very much. Sincerely, Ted Christopher, Rochester, NY.